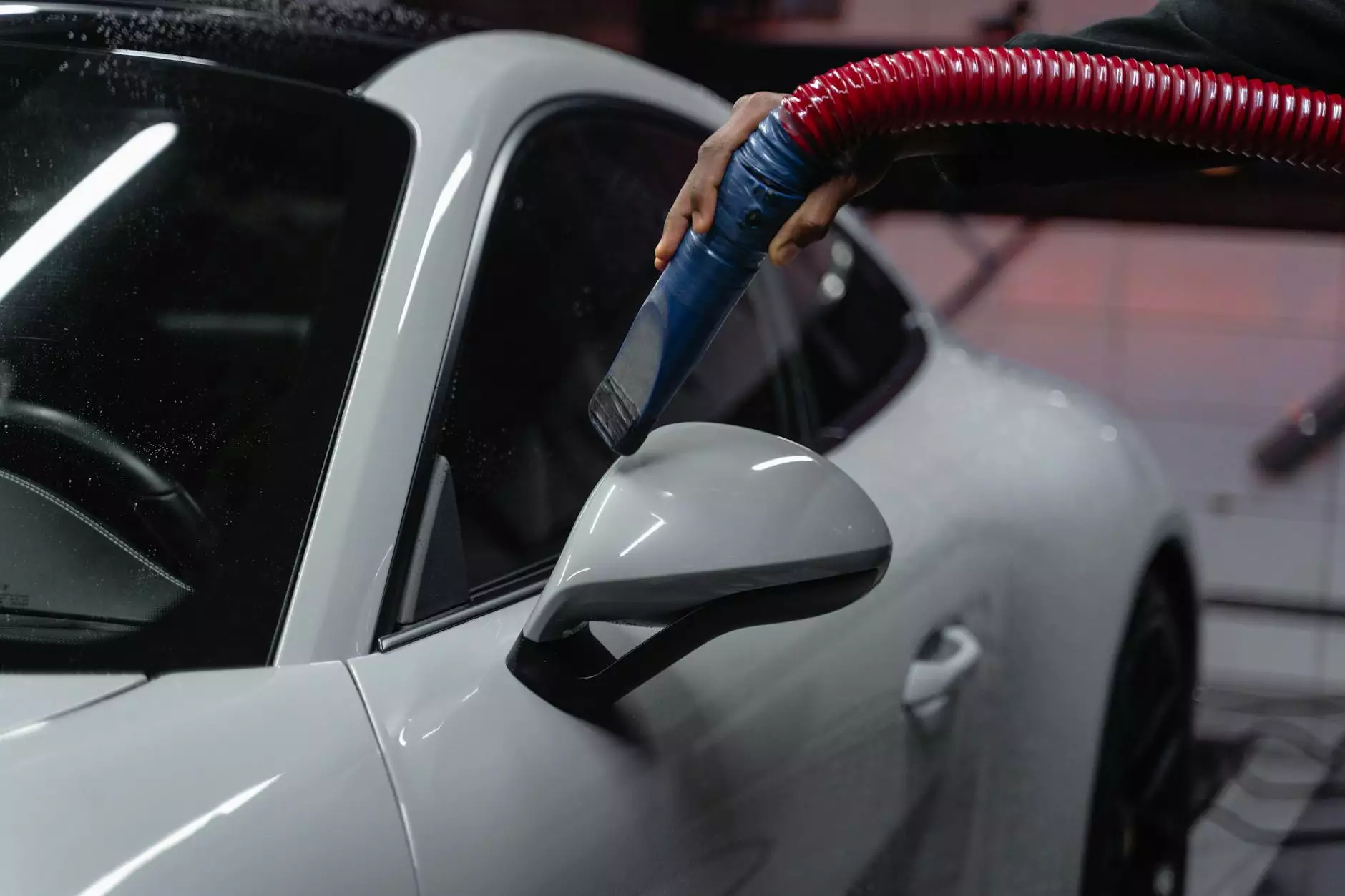

Industrial Vacuum Cleaning System: Revolutionizing Business Efficiency & Cleanliness

In the modern industrial landscape, maintaining impeccable cleanliness and ensuring operational efficiency are cornerstones of sustainable business success. The industrial vacuum cleaning system has emerged as a vital solution, transforming traditional cleaning practices with cutting-edge technology designed to meet the rigorous demands of diverse industries. From manufacturing plants to commercial facilities, this innovative cleaning system offers unparalleled advantages that propel businesses toward higher standards of hygiene, safety, and productivity.

What Is an Industrial Vacuum Cleaning System?

An industrial vacuum cleaning system is a specialized, high-capacity vacuum solution engineered for heavy-duty applications. Unlike conventional household vacuums, these systems are designed to handle vast amounts of debris, dust, liquids, and hazardous materials safely and efficiently. They incorporate robust components, powerful suction mechanisms, and advanced filtration technology to meet industrial cleanliness standards, ensuring contaminant-free environments essential for operational excellence.

Core Components of an Industrial Vacuum Cleaning System

- Heavy-duty vacuum motors: Provide exceptional power for continuous operation, capable of handling large debris loads.

- Durable collection tanks: Typically made of stainless steel or reinforced plastic, these tanks store collected waste securely, facilitating easy disposal.

- Advanced filtration systems: HEPA, ULPA, or other high-efficiency filters trap microscopic particles, ensuring purified exhaust air.

- Flexible hoses and tools: Enable access to hard-to-reach areas for comprehensive cleaning coverage.

- Automated features: Including automatic shutoff and self-cleaning mechanisms to optimize performance and reduce manual maintenance.

Benefits of Implementing Industrial Vacuum Cleaning Systems

Adopting an industrial vacuum cleaning system offers multifaceted advantages that directly impact business operations. These benefits include:

Enhanced Cleaning Efficiency

Industrial vacuum systems are engineered for rapid and thorough cleaning, drastically reducing the time required to maintain large facilities. Their high suction power combined with large capacity tanks enables the swift removal of debris, dust, and liquids, which is crucial for industries where cleanliness directly affects product quality and safety.

Improved Workplace Safety and Hygiene

Proper dust and waste management minimize airborne contaminants, creating a healthier environment for employees. In sectors like food processing, pharmaceuticals, and electronics, where contamination control is paramount, these systems ensure strict compliance with hygiene standards.

Cost Reduction and ROI

While the initial investment might be significant, the long-term savings are substantial. Reduced labor hours, lower cleaning costs, minimized equipment downtime, and compliance penalties avoidance all contribute to a favorable return on investment. Additionally, efficient waste collection reduces the need for frequent consumables and maintenance.

Environmental Sustainability

Modern industrial vacuum cleaning systems utilize eco-friendly technologies, such as energy-efficient motors and recyclable filters and tanks, helping businesses reduce their carbon footprint. Proper waste separation and disposal also promote sustainable practices.

Industries That Benefit Most from Industrial Vacuum Cleaning Systems

The versatility of these systems makes them suitable for a broad spectrum of industries, including:

- Manufacturing: For cleaning production lines, machinery, and workspaces contaminated with metallic shavings, dust, or chemical residues.

- Mining and Construction: To handle coarse debris, dust, and liquids generated during excavation and processing activities.

- Food Processing and Packaging: Ensuring dust and waste removal without compromising hygiene standards.

- Pharmaceutical and Chemical: Dealing with hazardous powders and liquids safely while maintaining strict sterility.

- Electronics and Semiconductor: Eliminating sensitive dust particles that could damage delicate components.

Key Features to Look for in an Industrial Vacuum Cleaning System

Investing in the right industrial vacuum cleaning system requires evaluating specific features to match your operational needs:

- Power and Suction Capacity: Ensure the system can handle the volume and type of debris expected.

- Filtration Technology: High-efficiency filters such as HEPA or ULPA for safe removal of microscopic particles.

- Mobility and Accessibility: Wheeled units and flexible hoses facilitate ease of movement and access.

- Durability: Heavy-duty construction materials prevent breakdowns and extend lifespan.

- Noise Levels: Quiet operation minimizes workplace disruptions.

- Compliance Standards: Devices that meet industry-specific safety and environmental regulations.

The Future of Industrial Cleaning: Smart and Sustainable Technologies

With rapid technological advancements, industrial vacuum cleaning systems are evolving towards smarter, more sustainable solutions. Integration with IoT (Internet of Things) enables enhanced monitoring and maintenance scheduling, reducing downtime and operational costs. Additionally, innovations in energy-efficient motors and biodegradable filtration media drive environmental sustainability efforts, aligning industrial practices with global green initiatives.

Why Choose tmm.com.tr for Industrial Vacuum Cleaning Systems?

As a leading provider in the sector, tmm.com.tr specializes in delivering customized, high-performance industrial vacuum cleaning systems tailored to your industry requirements. Their offerings include:

- Our extensive product range, designed to meet diverse operational demands.

- Expert consultation, ensuring you choose the optimal system for your facility.

- High-quality components, for durability and long-term reliability.

- Comprehensive after-sales support, including maintenance and upgrades.

- Competitive pricing, delivering value without compromising quality.

Implementing an Industrial Vacuum Cleaning System: Best Practices

To maximize the benefits of your investment, consider these best practices:

- Regular maintenance and inspections, to ensure consistent performance.

- Staff training, on proper operation and safety protocols.

- Customized cleaning schedules based on your facility’s specific needs.

- Waste management planning, to facilitate recycling and disposal.

- Continuous monitoring, using IoT-enabled systems for proactive maintenance.

Conclusion: The Strategic Advantage of Industrial Vacuum Cleaning Systems

Investing in an industrial vacuum cleaning system is no longer a luxury but a strategic imperative for modern businesses seeking to improve operational efficiency, ensure worker safety, and maintain exceptional hygiene standards. These systems offer a cost-effective, environmentally friendly, and technologically advanced solution to meet the complex demands of today’s industrial environment. Partnering with trusted providers like tmm.com.tr ensures access to cutting-edge technology and expert support, empowering your business to thrive in competitive markets.

By prioritizing quality cleaning solutions, you proactively safeguard your brand's reputation, compliance standing, and overall productivity. Embrace the future of industrial cleaning with the power of advanced industrial vacuum cleaning systems and witness your business attain new heights of excellence.